Magnet basics

What types of magnets are there?

There are three main types of magnets:

Permanent magnets

Temporary magnets

Electromagnets

Permanent Magnets

Permanent magnets are those we are most familiar with, such as the magnets hanging onto our refrigerator doors. They are permanent in the sense that once they are magnetized, they retain a level of magnetism. As we will see, different types of permanent magnets have different characteristics or properties concerning how easily they can be demagnetized, how strong they can be, how their strength varies with temperature, and so on.

Temporary Magnets

Temporary magnets are those which act like a permanent magnet when they are within a strong magnetic field, but lose their magnetism when the magnetic field disappears. Examples would be paperclips and nails and other soft iron items.

Electromagnets

An electromagnet is a tightly wound helical coil of wire, usually with an iron core, which acts like a permanent magnet when current is flowing in the wire. The strength and polarity of the magnetic field created by the electromagnet are adjustable by changing the magnitude of the current flowing through the wire and by changing the direction of the current flow.

Materials used for permanent magnets

There are four classes of permanent magnets:

Neodymium Iron Boron (NdFeB or NIB)

Samarium Cobalt (SmCo)

Alnico

Ceramic or Ferrite

This table gives us some of the special characteristics of the four classes of magnets.

Br is the measure of its

residual magnetic flux density in Gauss, which is the maximum flux the magnet is

able to produce. ( 1Gauss is like 6.45 lines/sq in)

Hc is the measure of the coercive magnetic field strength in

Oersted, or the point at which the magnet becomes demagnetized by an external

field. ( 1Oersted is like 2.02 ampere-turns/inch)

BHmax is a term of overall energy density. The higher the

number, the more powerful the magnet.

Tcoef of Br is the temperature coefficient of Br in terms of %

per degree Centigrade. This tells you how the magnetic flux changes with

respect to temperature. -0.20 means that if the temperature increases by

100 degrees Centigrade, its magnetic flux will decrease by 20%!

Tmax is the maximum temperature the magnet should be operated

at. After the temperature drops below this value, it will still

behave as it did before it reached that temperature (it is recoverable).

(degrees Centigrade)

Tcurie is the Curie temperature at which the magnet will become

demagnetized. After the temperature drops below this value, it will not

behave as it did before it reached that temperature. If the magnet is

heated between Tmax and Tcurie, it will recover somewhat, but not fully (it is

not recoverable). (degrees Centigrade)

(please note that this data is from www.magnetsales.com)

| Material | Br | Hc | BHmax | Tcoef of Br | Tmax | Tcurie |

| NdFeB | 12,800 | 12,300 | 40 | -0.12 | 150 | 310 |

| SmCo | 10,500 | 9,200 | 26 | -0.04 | 300 | 750 |

| Alnico | 12,500 | 640 | 5.5 | -0.02 | 540 | 860 |

| Ceramic or Ferrite | 3,900 | 3,200 | 3.5 | -0.20 | 300 | 460 |

Both the Neodymium Iron Boron and the Samarium Cobalt magnets are generally known as rare earth magnets since their compounds come from the rare earth or Lanthanide series of the periodic table of the elements. They were developed in the 1970's and 1980's. As can be seen in the table, these are the strongest of the permanent magnets, and are difficult to demagnetize. However, the Tmax for NdFeB is the lowest.

Alnico is made of a compound of aluminum, nickel and cobalt. Alnico magnets were first developed in the 1940's. As can be seen in the table, this magnet is least affected by temperature, but is easily demagnetized. This is the reason why bar magnets and horseshoe magnets made of alnico will easily become demagnetized by other magnets, by dropping it, and by not storing it with a keeper. Its Tmax, though, is the highest.

Ceramic or Ferrite magnets are the most popular types of magnets available today. The flexible magnets we use are a type of ceramic magnet, with the magnetic powders fixed in a flexible binder. These were first developed in the 1960's. This is a fairly strong magnet, not as easy to demagnetize as alnico, but its magnetic strength will vary the most as its temperature changes.

Shapes

Permanent magnets can be made in most any shape imaginable. They can be made into round bars, rectangular bars, horseshoes, rings or donuts, disks, rectangles, multi-fingered rings, and other custom shapes. Some are cast into a mold and require grinding to achieve final dimensions. Others start as a powder which is pressed into a mold or pressure bonded or sintered.

Here are some of the common types available for performing your experiments.

This is a small disk NIB magnet, about

0.50" diameter, 0.125" thick.

This is a small disk NIB magnet, about

0.50" diameter, 0.125" thick.

Arbor P8-1123, ScientificsOnline

35-105, AS&S , EdIn

This is a very small disk NIB magnet, about 3/16" diameter, 1/32"

thick, used for magnetic earrings.

This is a very small disk NIB magnet, about 3/16" diameter, 1/32"

thick, used for magnetic earrings.

Arbor, ScientificsOnline,

AS&S, EdIn

This is a larger disk NIB magnet, about 1"

diameter, 0.25" thick.

This is a larger disk NIB magnet, about 1"

diameter, 0.25" thick.

Arbor , ScientificsOnline

35-107, AS&S , EdIn

This is a small donut or ring ceramic magnet,

about 1.25" OD, 0.375" ID, 0.125" thick.

This is a small donut or ring ceramic magnet,

about 1.25" OD, 0.375" ID, 0.125" thick.

Arbor , ScientificsOnline

, AS&S , EdIn

This is a large donut or ring ceramic magnet,

about 2.75" OD, 1.125" ID, 0.50" thick. These have a lot of

pull!

This is a large donut or ring ceramic magnet,

about 2.75" OD, 1.125" ID, 0.50" thick. These have a lot of

pull!

Arbor , ScientificsOnline

37-621, AS&S , EdIn

This is a kidney shaped NIB magnet, about

7/8" by 0.50", 0.10" thick.

This is a kidney shaped NIB magnet, about

7/8" by 0.50", 0.10" thick.

Arbor , ScientificsOnline

, AS&S 29079, EdIn M-150

This is a trapezoidal shaped NIB magnet, about 1.25" by 0.75",

0.375" thick. These are very powerful!

This is a trapezoidal shaped NIB magnet, about 1.25" by 0.75",

0.375" thick. These are very powerful!

Arbor , ScientificsOnline

, AS&S , EdIn M-100

These are several marble magnets, each about

0.5" diameter.

These are several marble magnets, each about

0.5" diameter.

Arbor P8-1122, ScientificsOnline

34-968, AS&S , EdIn M-620

This is a wand ceramic magnet. They are

quite strong, great for experimenting.

This is a wand ceramic magnet. They are

quite strong, great for experimenting.

Arbor P8-1165, ScientificsOnline

, AS&S , EdIn M-510

This is a real alnico cow magnet.

This is a real alnico cow magnet.

Arbor , ScientificsOnline

31-101, AS&S , EdIn M-400

These are an assembled cow magnet.

These are an assembled cow magnet.

Arbor , ScientificsOnline

52-490, AS&S , EdIn M-450

This is an alnico horseshoe magnet. Please note the keeper on the end

of the magnet, which helps to prevent the magnet from becoming demagnetized.

This is an alnico horseshoe magnet. Please note the keeper on the end

of the magnet, which helps to prevent the magnet from becoming demagnetized.

Arbor , ScientificsOnline

, AS&S , EdIn

This is a long, narrow alnico bar magnet.

This is a long, narrow alnico bar magnet.

Arbor , ScientificsOnline

, AS&S , EdIn

This is a slightly flexible ceramic or ferrite disk magnet. Not very

strong, but not likely to chip, either.

This is a slightly flexible ceramic or ferrite disk magnet. Not very

strong, but not likely to chip, either.

Arbor , ScientificsOnline

, AS&S , EdIn

This is a ferrite bar magnet. Quite strong.

This is a ferrite bar magnet. Quite strong.

Arbor , ScientificsOnline

, AS&S , EdIn

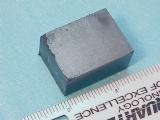

This is another ferrite bar magnet, actually, more like a block or

brick! On both of these ferrite magnets, you can see little chips missing

along the edges. This happens when they are allowed to come together

quickly.

This is another ferrite bar magnet, actually, more like a block or

brick! On both of these ferrite magnets, you can see little chips missing

along the edges. This happens when they are allowed to come together

quickly.

Arbor , ScientificsOnline

, AS&S , EdIn

This

is a string of 100 spherical magnets that stick to each other. These are a

lot of fun to play with - just not good for small children. You can make a

necklace, bracelet, ring, coils - all sorts of shapes. These are 1/4"

in diameter, and have a black nickel finish. They were from K&J

Magnetics, and cost about $60.

This

is a string of 100 spherical magnets that stick to each other. These are a

lot of fun to play with - just not good for small children. You can make a

necklace, bracelet, ring, coils - all sorts of shapes. These are 1/4"

in diameter, and have a black nickel finish. They were from K&J

Magnetics, and cost about $60.

How are magnets made?

There are 6 basic steps to making a magnet, such as a Neodymium Iron Boron magnet = Nd2Fe14B or Nd15Fe77B8.

1. Make an alloy of iron, boron and neodymium. You will need about 0.014 pounds of boron and 0.369 pounds of neodymium for every pound of iron to make an alloy of Nd2Fe14B. This will have to be heated above 1538 degrees Centigrade to make it melt. The mixing of the materials with the iron is very important, just like thoroughly mixing the ingredients for a cake.

2. Grind the alloy into a powder. After the alloy has cooled, you will need to grind it or mill it into a very fine powder.

3. Compress the powder into a shape. Since the magnet will have a specific shape when you are done, you use a mold of that shape to make the magnet. For example, you may want a disk. Pour the powder into a mold that has a disk shape, but is also deeper than the thickness of the final part. Next, you will compress the powder with hundreds of pounds of pressure to compact the powder into a solid disk. Heat is often used to help fuse the particles together, and is called a sintered magnet. Sometimes a glue is used to help keep it all together, and is considered to be a bonded magnet. To achieve precise final dimensions, you may need to grind the part.

4. Coat the magnet. In order to improve the corrosion resistance of the magnet, the disk needs to be plated with a thin film of nickel. Sometimes a film of gold is used, or zinc, or an epoxy coating.. Nickel does not oxidize like iron, so it works great for magnets you will be touching.

5. Magnetize the magnet. All this time, the powder and the disk is not magnetized. It would be attracted to and stick to a magnet, but it would not be able to pick up a paper clip all by itself. So, it would be placed into a magnetizing fixture that has a coil of wire through which a very large pulse of current is passed for a very short period of time. The magnet has to be held in place so it doesn't shoot out and hit something or someone. It takes about a thousandth of a second to actually magnetize the magnet.

6. Pack and ship it. You now have a magnet for whatever you need. Engineers often require special shapes or specific magnetization configurations to make the product they are designing work properly. They talk with the magnet manufacturer and they determine how to best make the magnet that is needed. That's why there are so many different shapes and sizes of magnets in the catalogs.

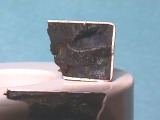

What does the inside of a magnet look like?

That's a great question! I have a donut or ring magnet that broke when it was dropped. I tried to glue it together with superglue, but I didn't put all of the pieces together at the same time, and now I can not fit the last piece in. (A broken bar magnet is easy to stick together while the glue is drying. Ring magnets don't want to stay together. Can you figure out why? Look at the field diagrams in the gallery.) So, now you can see what the inside looks like in the picture. The outside has a white epoxy coating. The inside is a simple dark gray or medium gray color, depending on what material it is made of. This was a ferrite magnet, so it is a dark gray color. By the way, the brownish circle on the magnet near my fingers is a felt pad I used to help prevent the magnet from crashing into another one. It didn't help much, did it? If the magnet isn't painted or coated, the inside looks just like the outside.

Magnetization configurations ![]()

How the magnet is magnetized is as important

as its shape. For example, a ring magnet can be magnetized where N is on

the inside and S on the outside, or N is on one edge and S on the opposite edge,

or N is on the top side and S on the bottom side, or multiple N and S poles all

around the outside edge, etc. A big help in visualizing how a magnet

may be magnetized is by using a magnetic

viewing film. Obtain one of these viewing cards, and look at the

magnets you have around your house. The white line marks the boundary

between the N and S poles. Make a sketch of what each magnet looks like

under the viewing film. You will be surprised by some.

Here is a great site that has drawings of several popular magnetization

configurations.

Here is a paper describing "Methods

of Magnetizing Permanent Magnets" by Joseph Stupak, Jr.

Oersted Technology makes magnetizers

and other products.

For more information:

For more information, please check this internal link.